May 28, 2021

The need for a more flexible and responsive manufacturing infrastructure has been apparent for some time. Periodic disruptions in the manufacturing chain caused by trade restrictions, freak weather, and shipping inefficiencies have stressed the just-in-time nature of manufacturing for years, and the recent pandemic made those problems even more apparent.

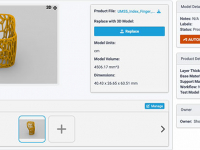

Digital manufacturing approaches can help companies make it easier to link design and production, increase visibility of the factory floor, and make it easier to re-tool and shift production in response to real-time supply and operational interruptions.

In this Special Focus Issue, our writers examine the use of digital twins in manufacturing and design, IP protection in a digital environment, and how a variety of different manufacturing sectors are embracing this change.

Inside This Issue:

Closed-Loop Digital Twin on the Factory Floor

A manufacturing closed-loop digital twin can use analytics and data to cut costs and avoid unplanned downtime.

Digital Transformation in Turbulent Times

The pandemic has prompted the increased use of design and simulation technologies to prepare for an uncertain future.

Autonomous Vehicle Design: Protecting Your Assets

Connected car designs bring new concerns surrounding IP and over-the-air hacking.

Making Connections for Digital Thread

APIs and data standards help PLM move forward and break down information silos.

Digital Twins Coming Into Focus

Augmented and virtual reality can help users better understand complex digital twin data.

Low Code Aims to Democratize Thread Development

The technology shows promise in overcoming many hurdles tied to realizing the full potential of the digital thread.

Factory Digital Twins Enhance Worker Safety and Supply Chains

How plant simulation and modeling technologies help enforce social distancing and safety practices.

Latest News