May 5, 2022

As components, parts, devices, and products are expected to last longer, perform better, be updated faster, and cost less, engineers are faced with increasingly complex design challenges that were unimaginable only a decade ago.

Adopting a modern workflow in the product development cycle liberates designers and engineers from legacy software constraints and hardware limitations resulting in less physical prototyping, mass-customized products, and budget optimization.

In this whitepaper, specialists from Onshape, SimScale, and ESTECO cover the implementation of a design-simulate-optimize workflow relying on tools built on the latest cloud computing and optimization technologies, applied to the design of a centrifugal fluid pump.

Fill out the information below to download the resource.

Latest News

Skip the Mesh, Print from CAD

Skipping the mesh and printing from CAD, some argue, is long overdue.

SPEE3D Collaborates With Northeastern University Kostas Research Institute

Purpose of collaborative effort is to bring additive manufacturing to students and military.

Azure Printed Homes Launches $4.2 MM Crowdfunding Campaign

Company named a 2025 SXSW Innovation finalist in Urban Experience for Sustainable Homes

JT File Importer Updated in KISTERS 3D CAD Visualization App

The new JT importer maximizes efficiency under multithreading demands.

Altair and Cranfield University Sign Simulation-Focused MoU

Organizations agree to advance use of simulation, data analytics, and AI.

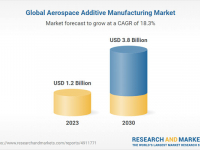

Role of Additive Manufacturing Through 2030

The global market for aerospace additive manufacturing is estimated at US$1.2 billion in 2023 and is projected to reach US$3.8 billion...

All posts

New & Noteworthy

New & Noteworthy: Future-Proof Foundation for Employee Training and Education

Eagle Point Software's Peak Experience for Pinnacle Series adds AI chat, improved...

Eliminate Physical Clamping – With Simulation

The Virtual Clamping tool in ANSA (VCA) from BETA CAE Systems eliminates...

New & Noteworthy: Fast, Flexible and Scalable Simulation – In the Cloud

Ansys Access on Microsoft Azure enables seamless deployment of industry-leading simulation tools...

New & Noteworthy: Safe, Cost-Effective Metal 3D Printing - Anywhere

Desktop Metal’s Studio System offers turnkey metal printing for prototypes and...